How technological innovation drives the development of PVC and PU coated oxford cloth

2024-09-26

In today's society, with the increasing awareness of environmental protection and the rapid development of science and technology, the field of materials science is undergoing unprecedented changes. PVC and PU coated Oxford cloth, as innovative applications of traditional materials, are continuously improving their performance, reducing costs, and broadening their application fields through a series of technological innovations.

Technological innovation improves performance

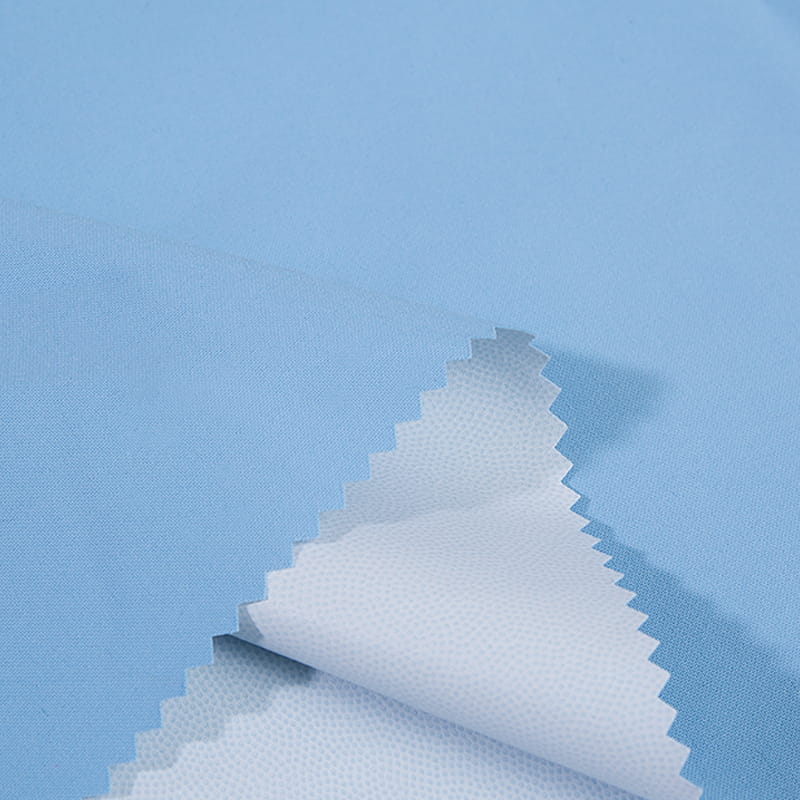

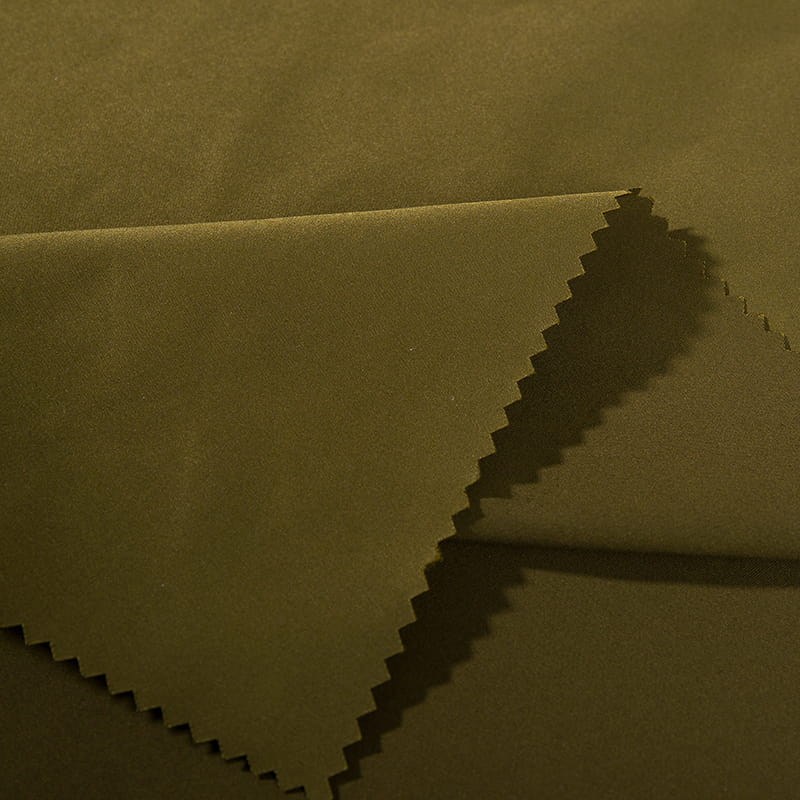

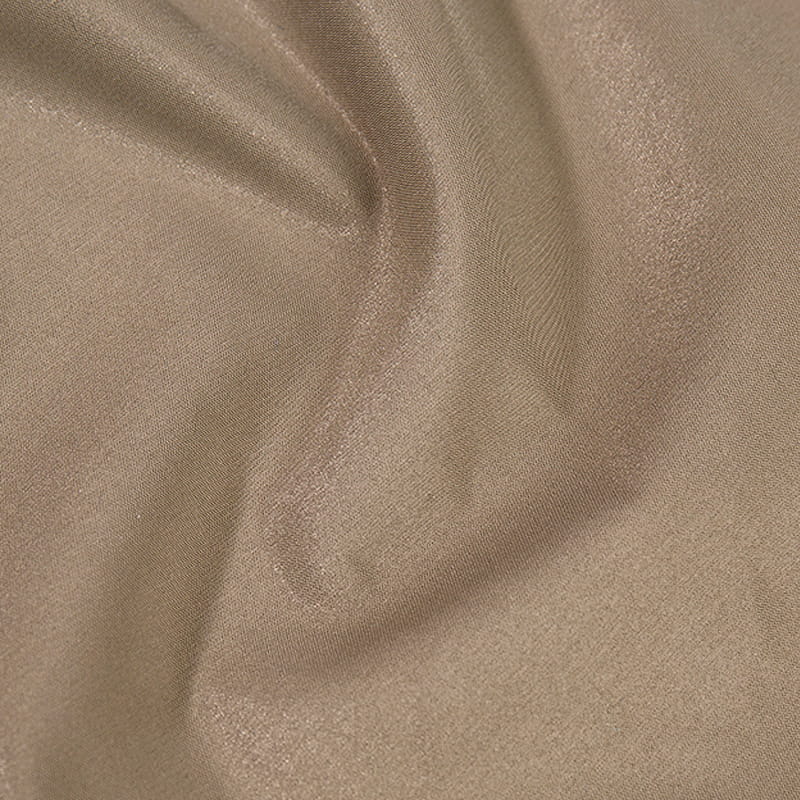

Technological innovation has played a key role in improving the performance of PVC and PU coated oxford fabrics. Traditional PVC-coated Oxford cloth is known for its excellent waterproof and windproof properties, but it has shortcomings such as easy aging and hard feel. By introducing new additives and modification technologies, the weather resistance and abrasion resistance of PVC coatings have been significantly improved, while maintaining its original waterproof properties. For example, using nanotechnology to modify PVC coating can make its surface smoother and reduce the adhesion of water droplets, thereby enhancing the waterproof effect.

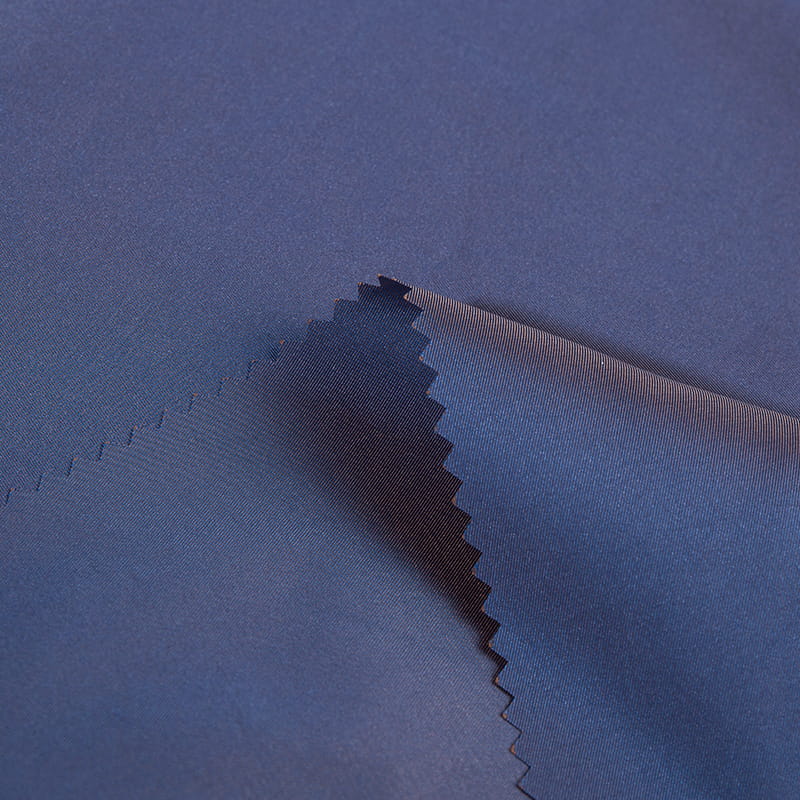

PU coated Oxford cloth is famous for its excellent elasticity, wear resistance and feel. In recent years, with the continuous advancement of polyurethane synthesis technology, the performance of PU coatings has been further improved. For example, by adjusting the molecular structure and cross-linking density of polyurethane, PU-coated Oxford cloth with higher elasticity and lower breathability can be prepared, which is suitable for a wider range of outdoor applications.

Environmental protection technology leads green development

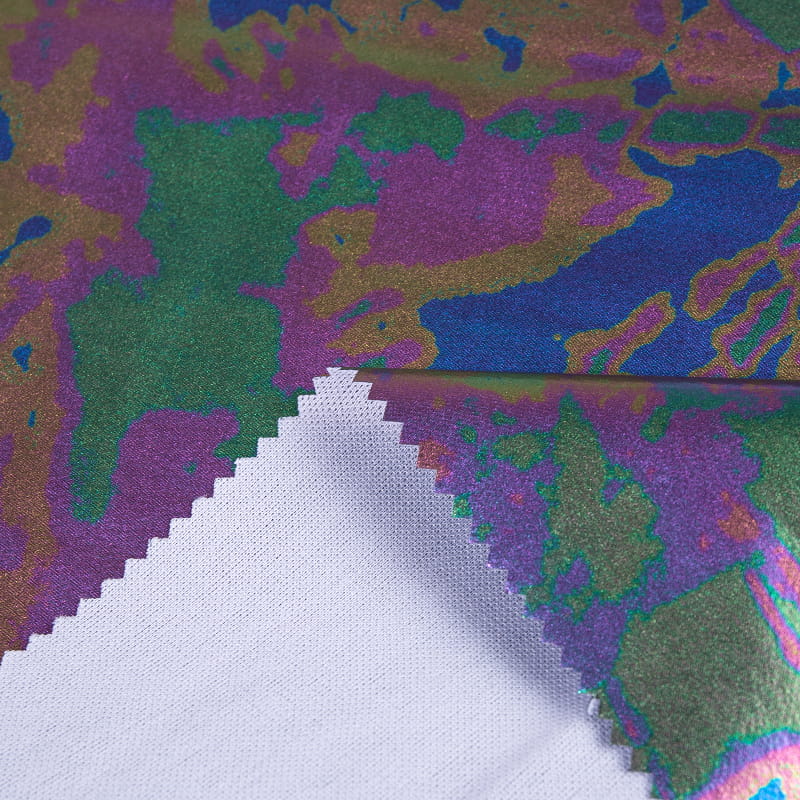

Innovation in environmentally friendly technology is an important driving force for the sustainable development of PVC and PU coated Oxford cloth. Traditional PVC coatings may release harmful substances during production and use, causing pollution to the environment. In order to solve this problem, scientific researchers have developed environmentally friendly PVC plasticizers, stabilizers and other additives to reduce the environmental risks of PVC coatings. At the same time, some companies have begun to explore the use of bio-based PVC raw materials, further reducing their dependence on fossil resources.

For PU coated Oxford cloth, innovation in environmentally friendly technology is equally important. By using water-based polyurethane technology, VOC (volatile organic compounds) emissions during the PU coating production process can be significantly reduced and the impact on the environment is reduced. In addition, some companies have also developed degradable PU coating materials, providing more possibilities for waste processing and resource recycling.

Intelligent production improves efficiency

The introduction of intelligent production technology is also an important factor in promoting the development of PVC and PU coated Oxford cloth. Traditional coating production lines often have problems such as high energy consumption and low efficiency. By introducing automation and intelligent equipment and technology, precise control, efficient operation, energy conservation and emission reduction of the production process can be achieved. For example, the use of intelligent robots to automate coating coating, drying and other processes can greatly improve production efficiency and product quality stability.

At the same time, intelligent production can also realize real-time collection and analysis of production data, providing more accurate and comprehensive information support for corporate decision-making. Through data analysis, companies can promptly discover problems in the production process and take measures to solve them, thereby further improving production efficiency and product quality.

Broaden application areas

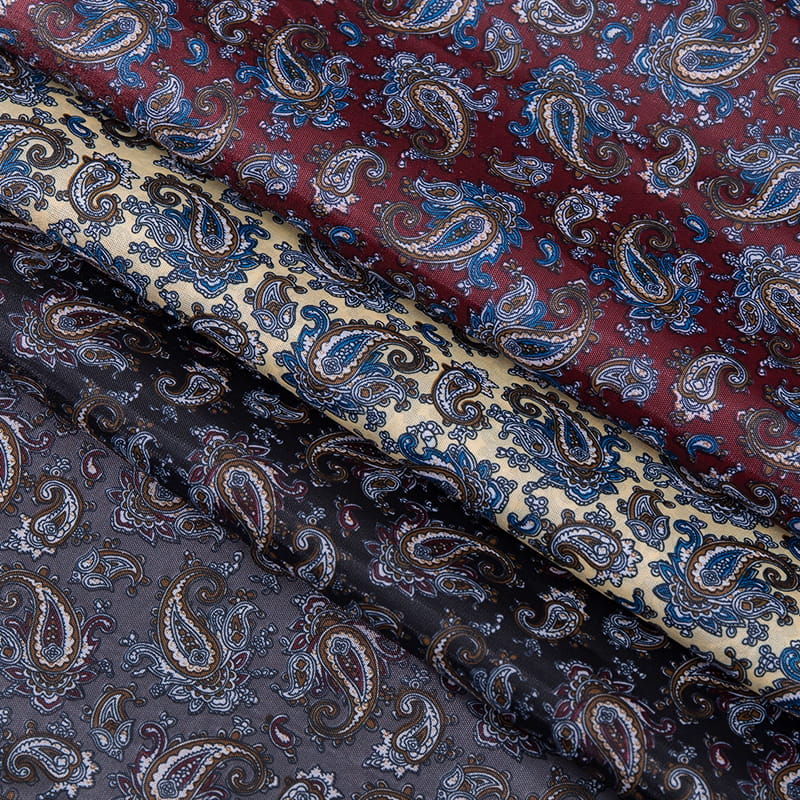

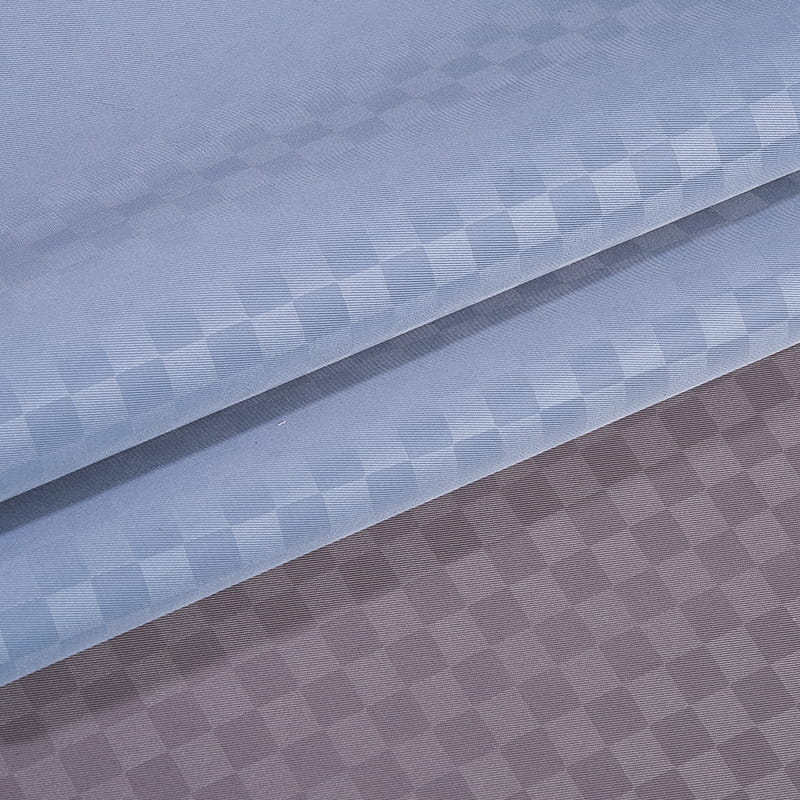

Technological innovation not only improves the performance and environmental protection of PVC and PU coated Oxford cloth, but also broadens its application fields. Traditional PVC-coated Oxford cloth is mainly used to make raincoats, tents and other outdoor products. With the continuous advancement of technology, PVC coated Oxford cloth has begun to be used in many fields such as construction, transportation, and medical care. For example, in the construction field, PVC-coated Oxford cloth can be used as waterproof membranes, sound insulation materials, etc.; in the transportation field, it can be used to make car interiors, ship decks, etc.

The application fields of PU coated Oxford cloth are equally wide. In addition to traditional clothing, luggage and other fields, PU coated Oxford cloth has also begun to be used in furniture, car seats, sports equipment and other fields. Its excellent elasticity, wear resistance and hand feel make PU coated Oxford cloth have broad market prospects in these fields.

English

English русский

русский عربى

عربى