What impact does the composite process have on the performance of Combined Polyester Fabric?

2024-05-23

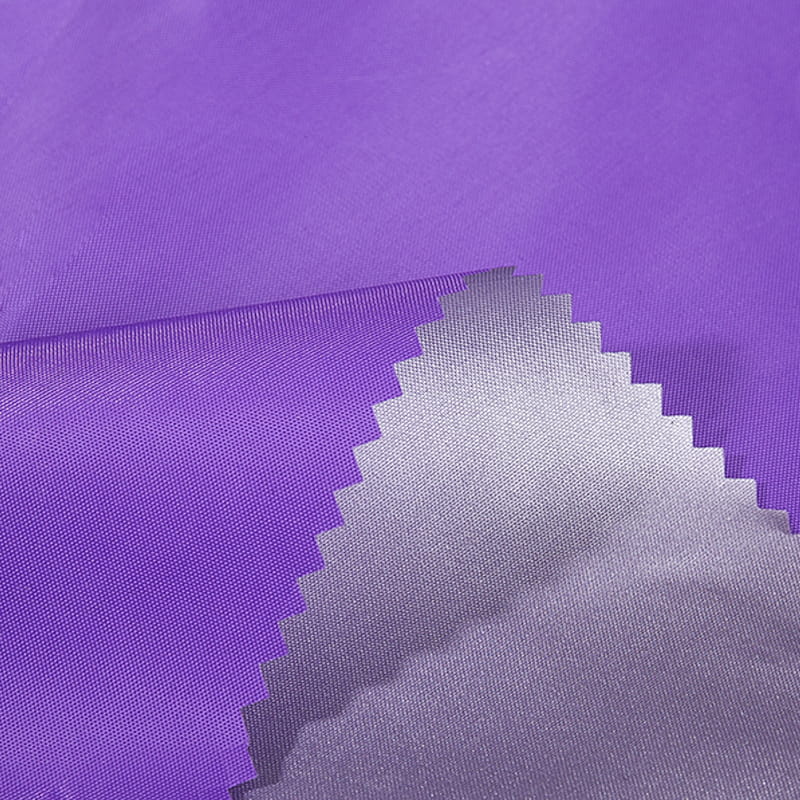

Combined Polyester Fabric is a fabric made of polyester fiber and cotton fiber through a composite process. This kind of fabric not only has the advantages of high strength, high modulus, and good dimensional stability of polyester fiber, but also has the softness, moisture absorption, breathability and other characteristics of cotton fiber. Therefore, it has a wide range of applications in clothing, home textiles and other fields.

1. Overview of composite technology

The composite process is to combine two or more fibers through specific processing methods to form a fabric with unique properties. In the compounding process of polyester-cotton blended fabrics, polyester fibers and cotton fibers are evenly mixed together, and the fabrics are made through processes such as spinning and weaving. This process can give full play to the advantages of both fibers while improving the performance of the fabric.

2. The impact of composite technology on the performance of Combined Polyester Fabric

Strength and wear resistance

In the composite process, polyester fiber and cotton fiber are evenly mixed together, making the fiber distribution in Combined Polyester Fabric more even. This uniform fiber distribution allows the fabric to evenly withstand stress, thereby increasing the overall strength of Combined Polyester Fabric. The composite process uses specific processing methods, such as spinning, weaving, etc., to tightly combine polyester fibers and cotton fibers. This tight combination reduces sliding and friction between fibers, further enhancing the strength of Combined Polyester Fabric. The high strength of polyester fiber and the softness of cotton fiber complement each other in composite fabrics. The addition of polyester fiber enhances the structural strength of the fabric, while cotton fiber makes the fabric softer and more comfortable while maintaining strength.

The high abrasion resistance of polyester fiber makes the fabric less prone to wear and tear when subjected to friction. In composite fabrics, the presence of polyester fiber effectively reduces wear and tear caused by friction and extends the service life of the fabric. The lamination process also enhances the fabric's wear resistance by improving its weather resistance. Polyester fiber has good weather resistance and can maintain stable performance under various environmental conditions. This allows Combined Polyester Fabric to exhibit better wear resistance in various environments.

Dimensional stability

Polyester fiber has excellent dimensional stability and is not easily deformed even when wet. Through the composite process, this stability is transferred to the Combined Polyester Fabric, so that the fabric maintains good dimensional stability during washing, drying, etc., and is not easy to shrink or deform.

Softness and feel

The softness and skin-friendliness of cotton fiber make Combined Polyester Fabric more comfortable to the touch. The composite process not only maintains the excellent properties of polyester fiber, but also retains the softness of cotton fiber, making the fabric softer to the touch and suitable for close-fitting wear.

Hygroscopicity and breathability

Cotton fiber has good hygroscopicity and breathability, while polyester fiber has poor hygroscopicity. Through the composite process, the hygroscopicity of polyester fiber can be improved to a certain extent, so that the fabric can maintain a certain degree of hygroscopicity and breathability while maintaining the excellent properties of polyester fiber. This characteristic makes the fabric more comfortable and less likely to cause stuffiness during wearing.

Wrinkle resistance and shape retention

Polyester fiber has high modulus and excellent elasticity, giving the fabric good wrinkle resistance and shape retention. While maintaining this characteristic, the composite process also improves the shortcomings of cotton fibers that are prone to wrinkles, making the fabric less prone to wrinkles during wearing and washing, and remains smooth and beautiful.

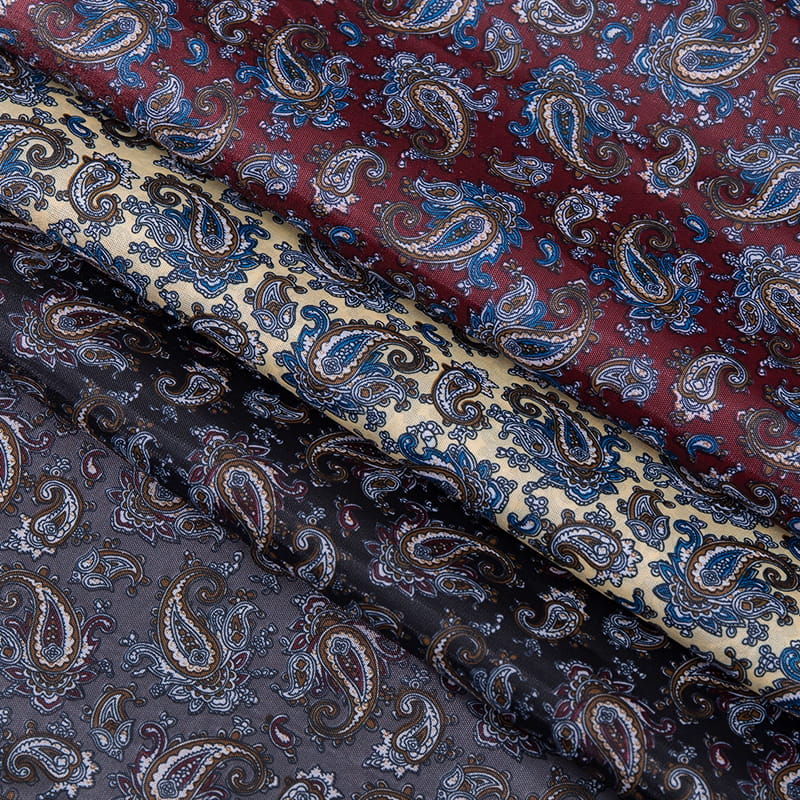

Aesthetics

The composite process allows a variety of dyeing and printing techniques to be used in the fabric production process, which makes Combined Polyester Fabric very rich in color options. Both polyester fiber and cotton fiber can be dyed in various colors, and these two fibers have good dyeing performance, bright colors and not easy to fade. Therefore, through the composite process, brightly colored and colorful polyester-cotton blended fabrics can be produced to meet consumers' needs for different colors and patterns. The composite process also gives Combined Polyester Fabric more possibilities in pattern design. Both polyester fiber and cotton fiber can be printed, and the printing effect is clear and long-lasting. Through the composite process, various patterns and texture designs can be integrated into the fabric, making the fabric more visually beautiful and attractive. These patterns can be simple geometric figures, natural landscape patterns, or complex abstract art patterns, adding more artistic flavor and fashion sense to the fabric.

English

English русский

русский عربى

عربى