What is the cause of the visible scars on the PVC lining?

2024-07-25

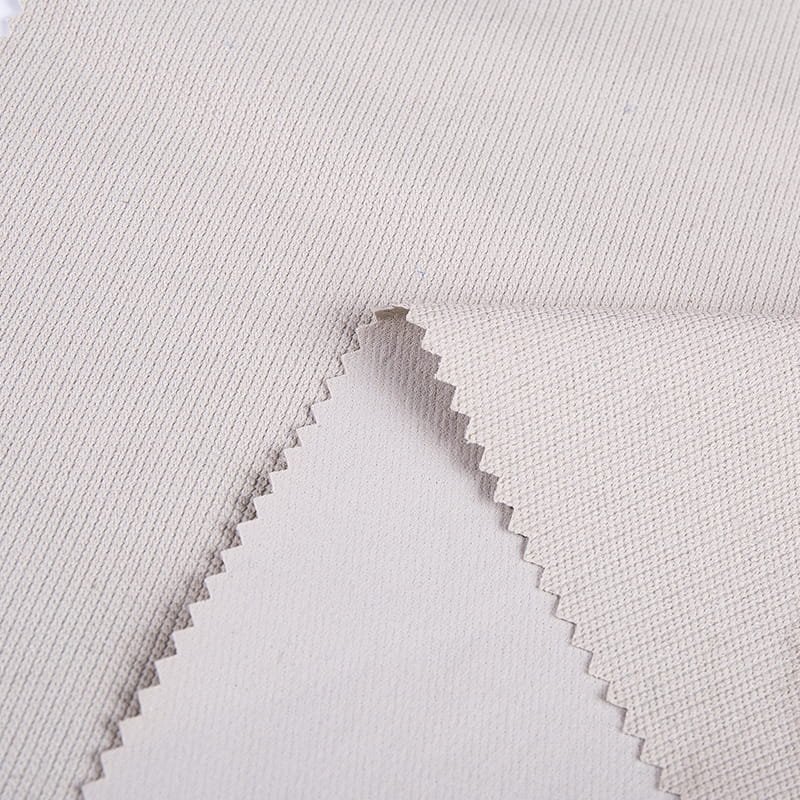

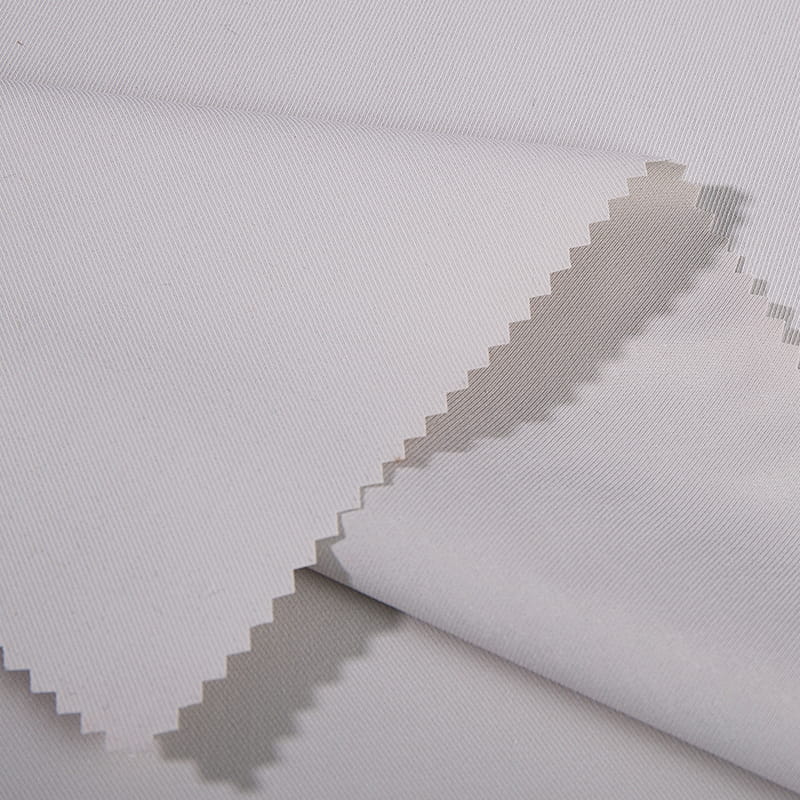

1. Raw material production technology 1. Raw material quality The performance of PVC coatings has been greatly improved due to its raw material quality. As a result, the raw material quality of PVC resin, plastic resin, adhesive, etc. is not good, or the ratio is unreasonable, and the physical performance (hardness, abrasion resistance) of the resin is reduced, so it is easier to achieve. Trace impact. For example, a certain low-quality PVC resin can contain a lot of quality or strength, and a certain low-quality urban treatment performance.

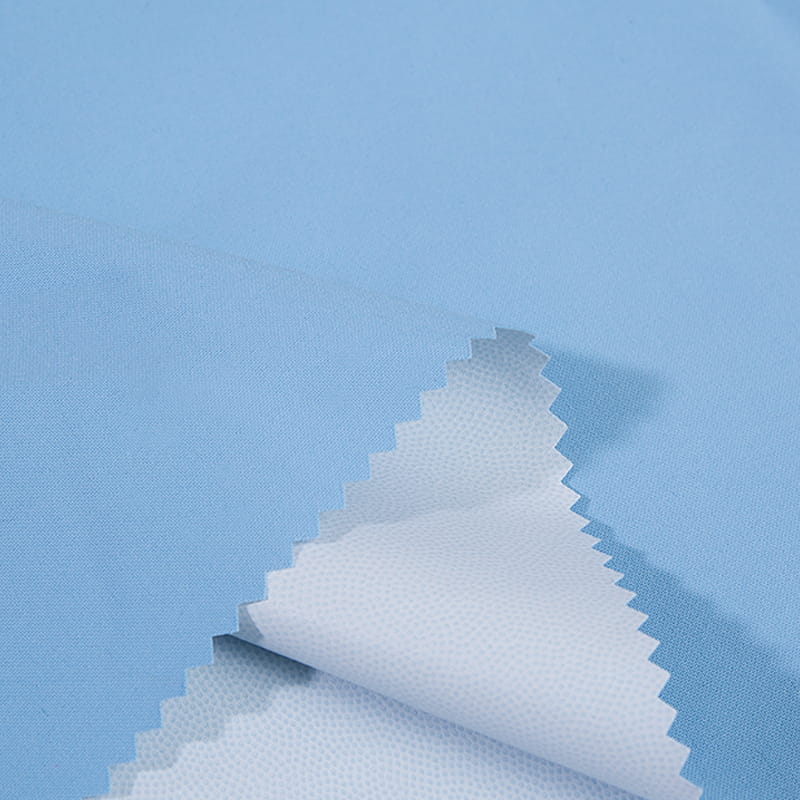

2. Production engineering control The production engineering control is also a key factor in the performance of the PVC coating. During the life cycle, as a result of uneven thickness of the layer, insufficient solidification, improper temperature control, etc., it is possible that the surface of the layer may be weakened or weakened, and there may be small areas that are easily affected by external forces. In addition, the combined force between the layers and the base fabric is not strong, and it is also easy to guide the layers and fall off or produce traces during friction.

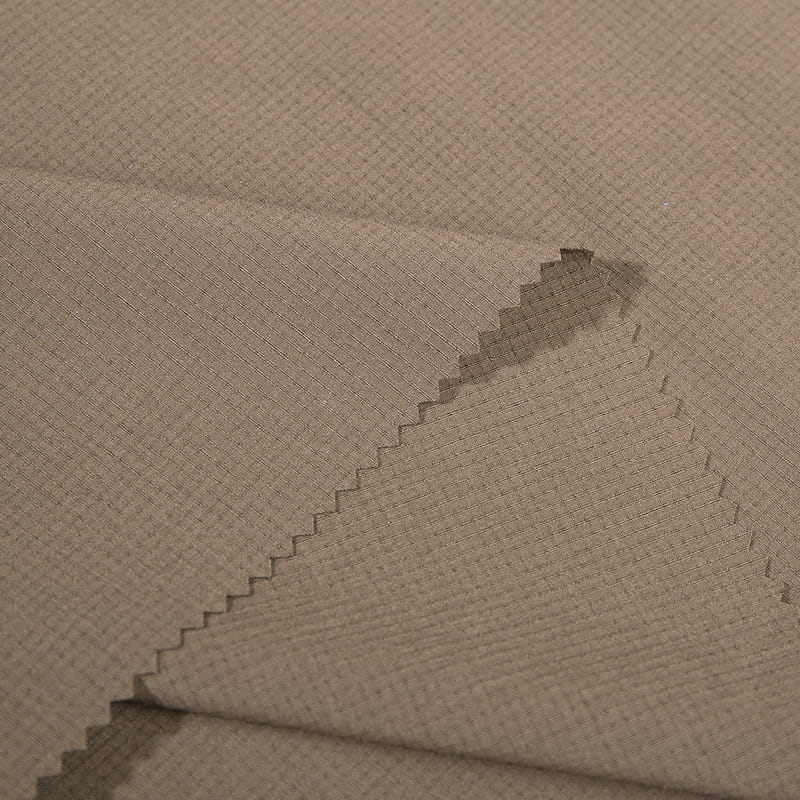

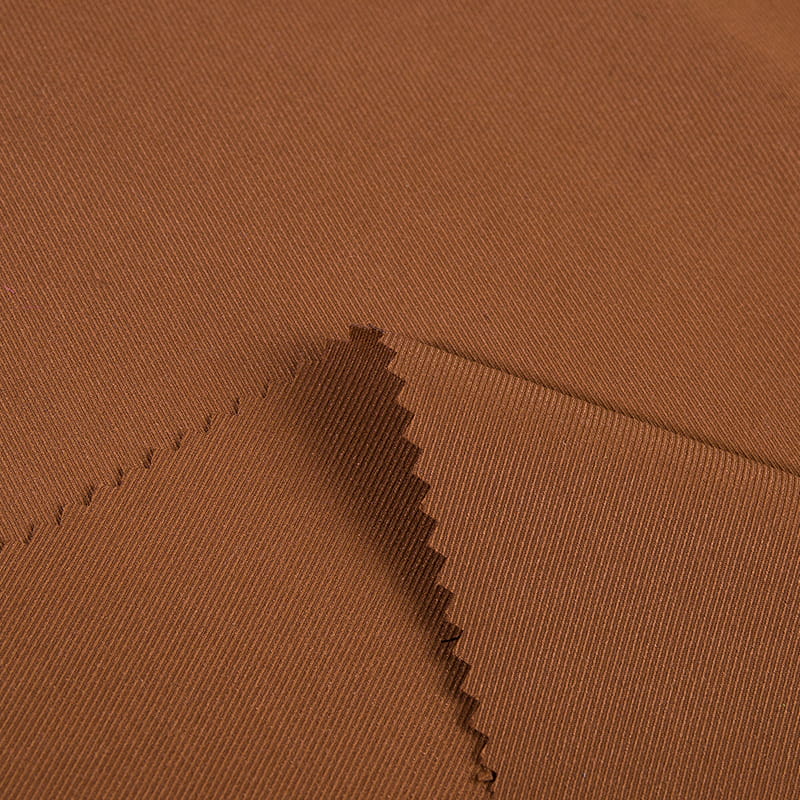

2. Conditions of use 1. Friction and friction During the use of PVC fabric, there are various external forces that meet the regular demand for friction and friction. For example, during transport, folding, installation or cleaning, if the object is sharpened, rough surface or hard object comes into contact, it may be possible to guide the surface of the layer to reveal scratches. In particular, under the external environment, natural factors such as wind, sand, etc. may also cause damage to the construction of the tank.

2. Chemical quality violation: Certain chemical quality may also cause damage to PVC layer construction, resulting in the appearance of traces. For example, the chemical structure of corrosive materials such as strong acid, strong red, etc., has abrasion resistance and scratch resistance. In addition, there is a small amount of organic dissolution that can also cause the layer to have a biologically dissolving effect, so that its surface can be changed to coarseness or decomposition.

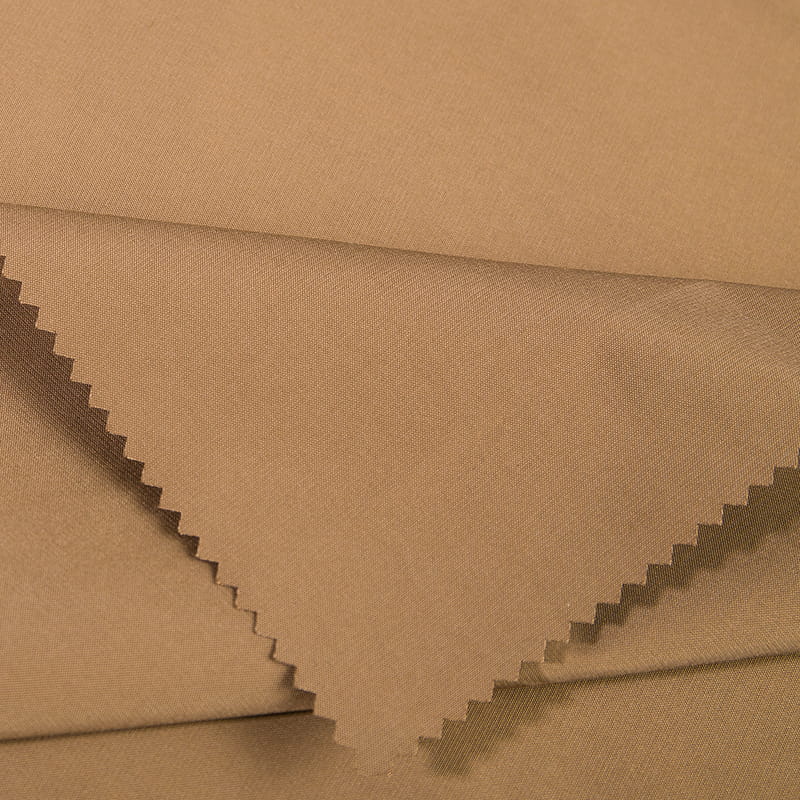

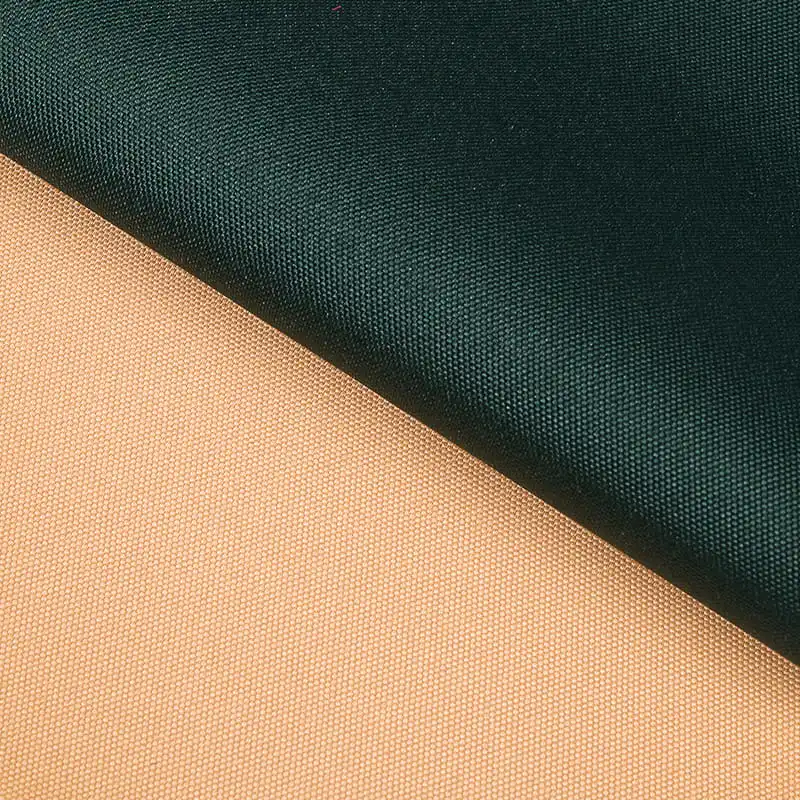

3. Cleaning and protection 1. Inappropriate cleanliness method It is also possible to introduce the cleanliness method of the PVC coating. For example, when using coarse cleaning tools (such as iron balls, hard bristle brushes) or containing corrosive ingredients, it is possible to damage the surface of the layer.

2. During the process of transferring the existing release and transfer, if the PVC layer is received by the user, there may be some unjustified procedures such as folding or editing, and there may be traces of deformation on the surface of the layer. In particular, under long-term transportation or adverse weather conditions, please note the need for replacement and protect the product.

The causes of the appearance of PVC coatings are multifaceted, including raw materials production technology, usage environment and conditions, protection and protection, etc. In order to reduce the appearance of small scratches, the demand should be controlled by the quality of the raw materials, the quality of the production process should be controlled; during the use process, be careful to avoid contact with the tip of the object, select the appropriate clean method, and save the transportation method; It has a long service life since its operation and protection.

In order to solve the problem of the appearance of the original production, it is possible to use it in order to make further modifications in the production system. However, it is necessary to pay attention to the fact that the effect of correction is possible because of the depth of the effect, the surface area, and the location of the factors. In this case, due to increased demand in the area of production, caution should be taken to implement measures.

English

English русский

русский عربى

عربى