How can polyester fabrics reduce energy consumption and reduce environmental pollution?

2024-06-27

As global environmental problems become increasingly severe, the textile industry is also actively seeking more environmentally friendly and sustainable production methods. As an important member of the textile field, the control of energy consumption and environmental pollution in the production process of composite polyester fabrics is particularly important.

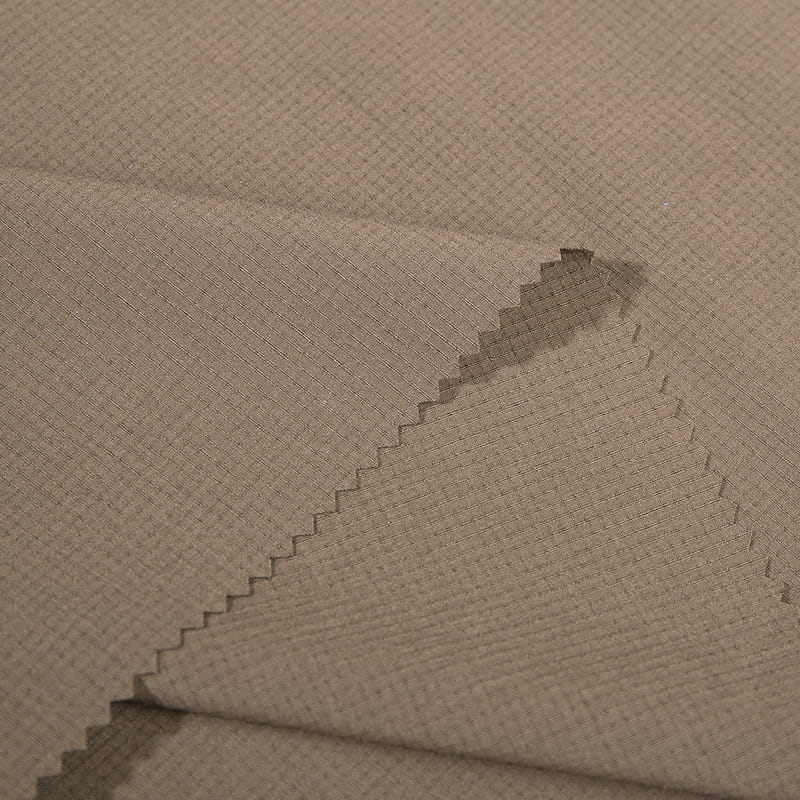

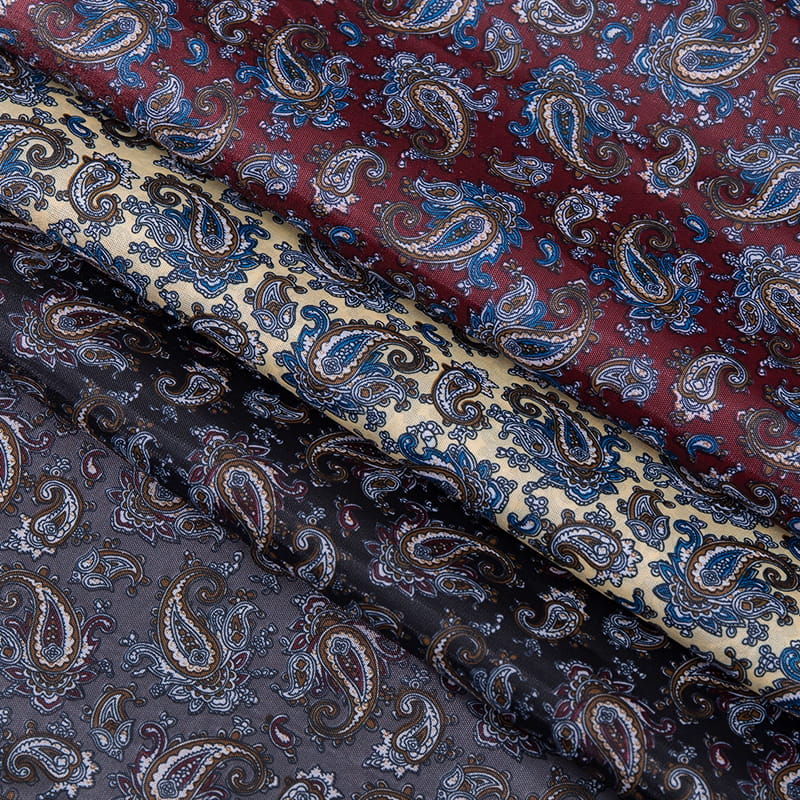

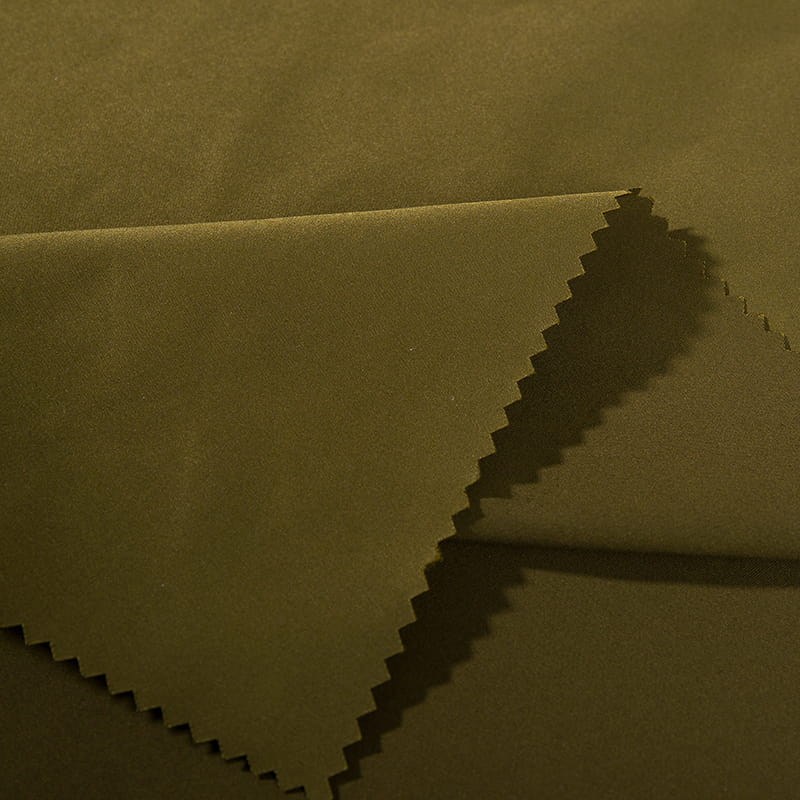

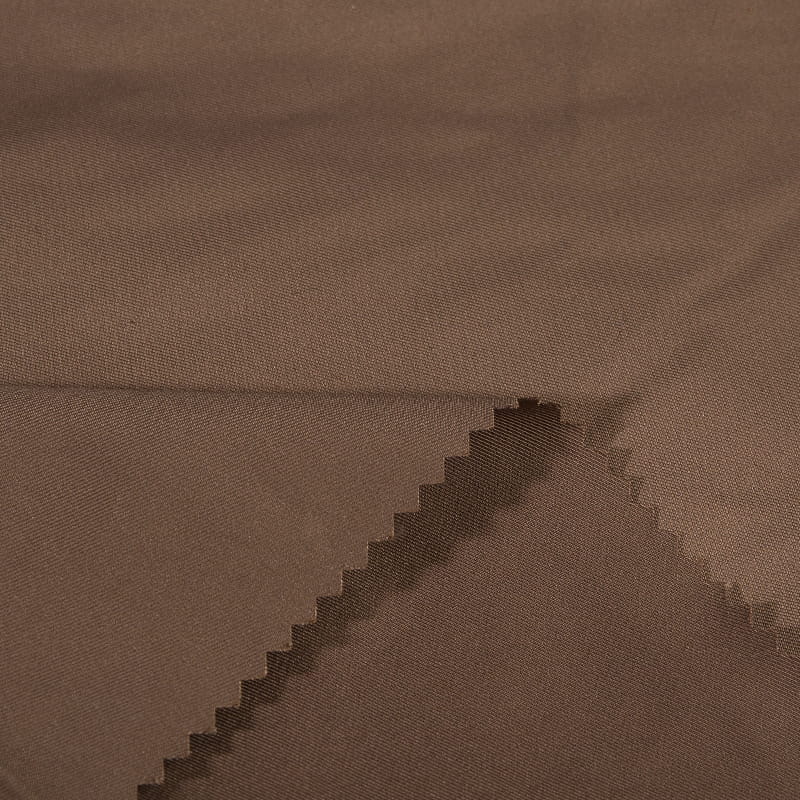

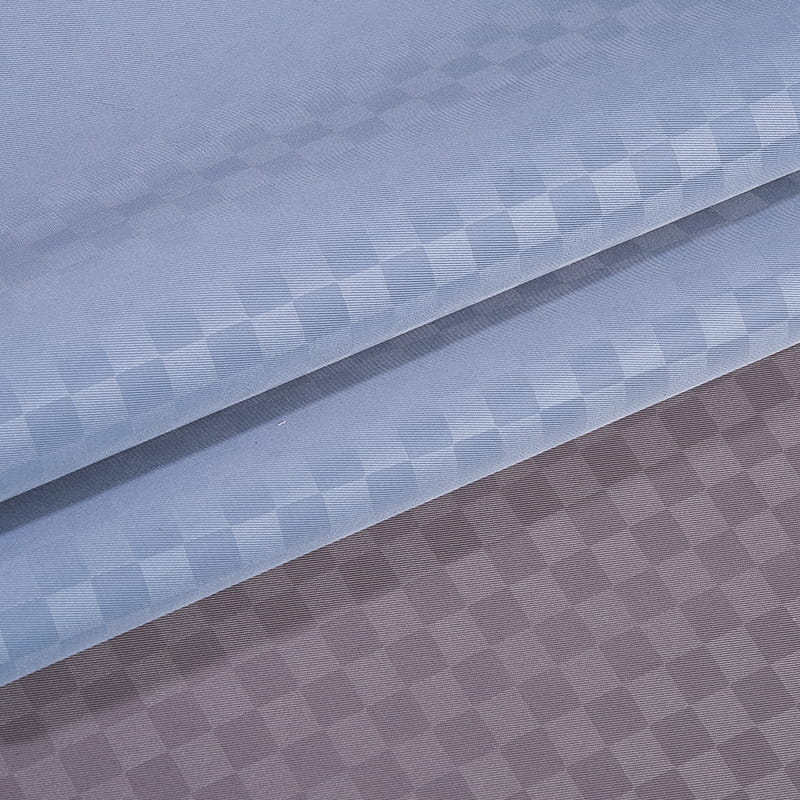

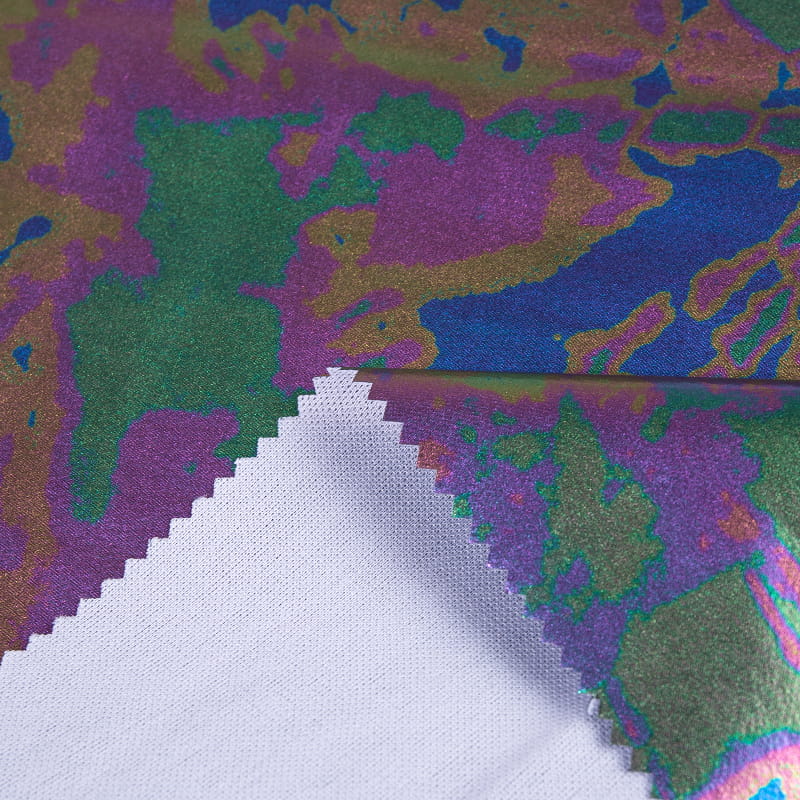

1. Characteristics and advantages of composite polyester fabrics

Combined Polyester Fabric is a kind of fabric made by combining polyester fibers with other fibers through a special process. It combines the characteristics of high strength, good elasticity, and good wear resistance of polyester fibers, and at the same time can improve its hygroscopicity, breathability and other performances through compounding with other fibers. The diversity and adaptability of this fabric make it widely used in clothing, home textiles, decoration and other fields.

2. Measures to reduce energy consumption

Optimize production process: In the production process of Combined Polyester Fabric, the use of advanced production equipment and processes can greatly improve production efficiency and reduce energy waste. For example, the use of high-efficiency and energy-saving spinning equipment, weaving equipment and finishing equipment can reduce energy consumption while ensuring product quality.

Intelligent control: By introducing intelligent control systems, each link in the production process can be precisely controlled to avoid unnecessary energy waste. The intelligent system can adjust the equipment operation status in real time according to production needs to achieve efficient use of energy.

Energy-saving raw materials: Selecting energy-saving raw materials is also an important measure to reduce energy consumption. For example, the use of low-energy polyester fibers and environmentally friendly dyes can reduce energy consumption and waste emissions in the production process.

3. Ways to reduce environmental pollution

Environmentally friendly dyes and auxiliaries: In the dyeing and finishing process of Combined Polyester Fabric, the use of environmentally friendly dyes and auxiliaries can reduce the emission of wastewater, waste gas and solid waste. These environmentally friendly materials have the characteristics of low toxicity and easy degradation, and have less pollution to the environment.

Wastewater treatment: The wastewater generated in the production process of composite polyester fabrics contains a large amount of harmful substances and must be strictly treated before it can be discharged. Enterprises can introduce advanced wastewater treatment equipment and technology to deeply treat wastewater to ensure that the discharged water quality meets environmental protection standards.

Waste gas treatment: Waste gas treatment is the key to reducing air pollution in the production process of composite polyester fabrics. Enterprises can reduce the emission and pollution of waste gas by installing waste gas treatment equipment and adopting clean production technology.

Resource utilization of solid waste: Solid waste generated in the production process of composite polyester fabrics can be recycled. For example, waste silk and waste cloth can be recycled to reduce production costs; waste that cannot be reused can be used for energy through incineration and other methods.

As an important textile material, the environmental performance of composite polyester fabrics is of great significance to the sustainable development of the entire textile industry. By optimizing production processes, adopting intelligent control, selecting energy-saving raw materials, and implementing environmentally friendly dyes and auxiliaries, energy consumption and environmental pollution in the production process of composite polyester fabrics can be significantly reduced. At the same time, enterprises should also strengthen wastewater treatment, waste gas treatment and solid waste resource utilization to promote the green development of the composite polyester fabric industry.

English

English русский

русский عربى

عربى