How is the weather resistance of PU WATERPROOF OXFORD FABRIC?

2024-12-19

1. Basic characteristics of PU waterproof Oxford fabric

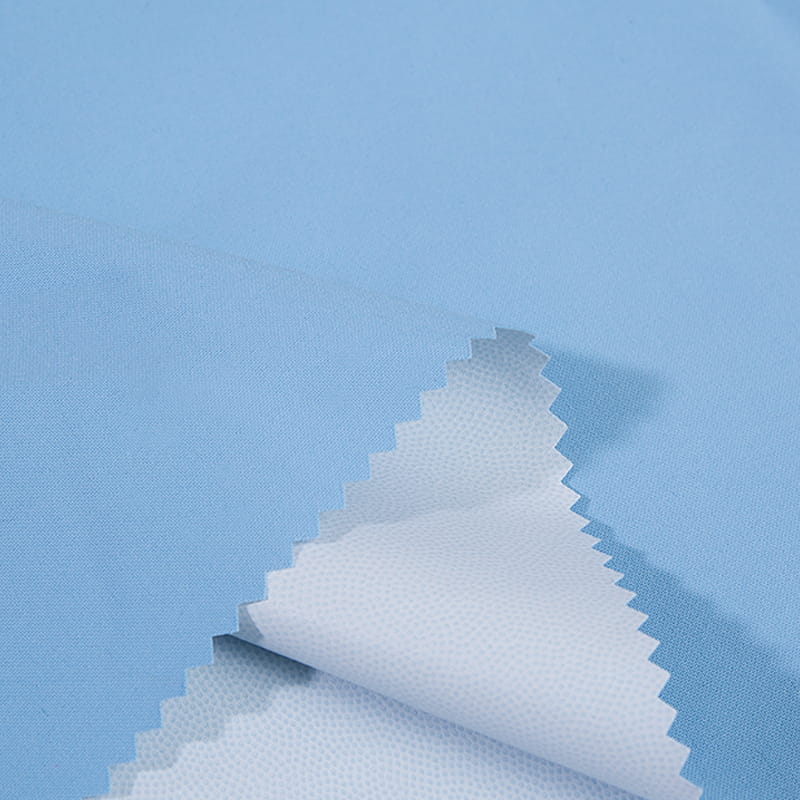

The basic composition of PU waterproof Oxford fabric is composed of a specially treated high-strength Oxford fabric base and a PU coating coated on its surface. The PU coating gives this type of fabric the ability to be waterproof, wear-resistant and oil-resistant, so it is widely used in the production of various outdoor products and waterproof clothing. Compared with traditional PVC-coated Oxford fabric, PU-coated materials are softer, more comfortable to the touch, and have higher breathability, making them an ideal choice for clothing and backpacks that require breathability.

Although PU-coated Oxford fabric has excellent flexibility and comfort, its weather resistance faces some challenges, especially when exposed to sunlight, high temperature and humidity for a long time.

2. Weather resistance issues of PU waterproof Oxford fabric

(1) UV aging

PU coatings are more susceptible to ultraviolet (UV) radiation than PVC coatings. Ultraviolet rays can destroy the chemical structure in the coating, leading to material degradation. Specifically, ultraviolet rays can break the molecular chains in the PU coating, which in turn leads to brittleness, fading and reduced waterproofing of the coating. PU coated Oxford fabric exposed to sunlight for a long time will gradually become hard, lose its original softness and elasticity, and even crack or peel off.

This UV-induced aging phenomenon usually shortens the service life of PU waterproof Oxford fabric, especially in outdoor environments, such as tents, outdoor furniture covers or camping backpacks, when they are often exposed to sunlight. Therefore, for PU coated Oxford fabric products used outdoors for a long time, special attention should be paid to the damage of UV rays to the coating and excessive exposure should be avoided.

(2) Effects of high temperature and humidity

High temperature and humidity are two other important factors that affect the weather resistance of PU waterproof Oxford fabric. PU coating has poor high temperature resistance, especially in an environment above 60°C, PU coating is prone to softening, adhesion or deformation. PU waterproof Oxford fabric used in high temperature environment may lose its original waterproof function and strength, and the surface may become discolored or dented, affecting the appearance and practicality.

Humidity and moisture can also have an adverse effect on PU coated Oxford fabric. In a humid environment, PU coating materials may absorb moisture, resulting in a decrease in the water resistance of the coating. Moisture and water accumulation will accelerate the aging process of PU coatings. Long-term humid environment may also cause the coating to mold or corrode, especially in the absence of adequate ventilation.

(3) Effect of low temperature

Although PU coatings perform slightly better than PVC coatings in low temperature environments, PU coatings may still become brittle in extremely cold climates. When the temperature drops below -20°C, the flexibility and durability of the PU coating will be significantly reduced, resulting in cracks or peeling on the coating surface. This may affect the performance of PU waterproof Oxford fabric products during outdoor activities in cold areas. Therefore, special attention should be paid to occasions used in extremely cold weather.

3. How to improve the weather resistance of PU waterproof Oxford fabrics

In order to improve the weather resistance of PU waterproof Oxford fabrics and extend their service life, manufacturers usually take some measures to enhance their UV resistance, anti-aging and high temperature resistance:

(1) Adding UV inhibitors

Some high-quality PU coatings will add UV inhibitors to improve the UV resistance of the coating. These UV inhibitors can effectively reduce the damage of UV rays to the PU coating and delay the aging process caused by UV rays, thereby improving the weather resistance of PU waterproof Oxford fabrics.

(2) Optimize the PU coating formula

In modern manufacturing processes, manufacturers will optimize the formula of PU coating to enhance its resistance to high temperature and moisture. Some PU coatings add high temperature plasticizers or heat stabilizers to improve their stability in high temperature environments, while also increasing the coating's resistance to moisture.

(3) Use high-performance PU coatings

In recent years, with the advancement of technology, some high-performance PU coating materials have appeared on the market. These coatings not only have excellent waterproof properties, but also have stronger anti-aging and weather resistance. For example, the use of solvent-free PU coatings is not only environmentally friendly, but also can improve the durability of the material.

(4) Reasonable use and maintenance

For consumers, proper maintenance and use can also help extend the service life of PU waterproof Oxford cloth. For example, try to avoid long-term exposure to the sun, clean it in time after use and store it in a dry and ventilated environment, which can effectively reduce the impact of moisture on the coating.

English

English русский

русский عربى

عربى